How the issue of galvanic corrosion affects installation of stainless steel trefoil cleats onto galvanised steel support structures in various environments.

The term galvanic corrosion refers to corrosion induced when there is electrical contact between two dissimilar metals in the presence of an electrolyte, i.e. water or corrosive vapour. The severity of the corrosion is determined by whether the metal is deemed cathodic, e.g. 316 stainless steel in its passive state, or anodic, e.g. zinc (the predominant metal of galvanised coatings).

In the majority of cable cleat installations, galvanic corrosion is not experienced due to the lack of an electrolyte in the atmosphere. Stainless steel has an inherent chrome oxide film layer which protects it from the environment, in what is deemed an “active” state, this layer can however be eroded in the presence of halogen salts in the form of fluorine, chlorine, bromine, iodine or astatine, many of which can be found in contaminated water or gas vapour. As the majority of ETS stainless steel cable cleats are installed within dry industrial or commercial environments, without the presence of any electrolyte and remaining in their “active” state, galvanic corrosion does not occur between the cleat and the surrounding galvanised steel support structure.

Cause and effect of galvanic corrosion

Galvanic corrosion is an issue which must be addressed in areas contaminated with high levels of halogen salts, namely exposed environments close to the sea or areas prone to contaminated rainfall, e.g. major conurbations and oil or gas fuelled power stations etc. In such areas the integrity of the stainless steel product is attacked by these halogen salts, breaking down the protective chrome oxide film, making the material deemed to be “passive” in its characteristics. Over a period of time and in the continual presence of an electrolyte, any zinc coated (galvanised) structure is adversely affected, dissolving the zinc and corroding faster than it would if not in contact with the passivated stainless steel, which conversely corrodes slower! In real terms, this means that the galvanised coated steel-work would corrode due to the loss of its zinc coating, although the stainless steel cleat suffers no adverse effects.

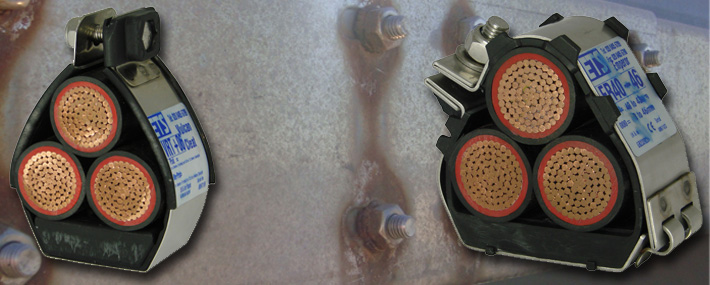

Avoid galvanic corrosion with a 91-ST washer

To overcome the issue of galvanic corrosion in such areas, we recommend the use of the 91-ST cleat separation washer. This provides an insulation layer between the dissimilar metals, increasing the distance between each metal and removing the electrical and physical contact points critical to the development of corrosion.

The importance to this process of time and “wetness” (as well as the chemical characteristics of the “wetness”) should be stressed. There is no definite period of time which can be mentioned as there are so many variables to the process, consideration should be paid to the projected life-span of the installation and the potential corrosiveness of the environment. In general terms, we would advise the use of the cleat separation washer for all external installations.

If you found this article helpful or interesting, please share it!