25 Major Construction and Infrastructure Projects That Weren’t Here 25 Years Ago

To celebrate our 25 years of service to the electrical industry, we’ve picked 25 of the most interesting, impressive and astonishing building and infrastructure projects from around the world, that were not here when we started business. We’ve witnessed some amazing mega-projects and feat of engineering in the past quarter of a century. As a […]

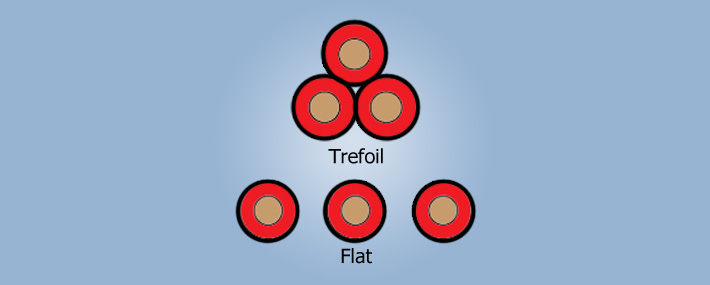

Single-Core Cables Laid in Trefoil or Flat Formations – Advantages & Disadvantages

Single-core power cables can be run in a number of formations, the most common include flat or trefoil formations. Each cable formation has its benefits and drawbacks, we’re going to look at the differences between each way for laying these cables. Trefoil Phase Formation One of the main reasons trefoil formations are used is that […]

Nexans WINDLINK Offshore Junction Cabinets for Offshore Wind Farms

Nexans WINDLINK enclosures for offshore wind farms aim to reduce installation time on site as well as offering considerable cost savings. The available range of offshore junction cabinets (OJC) and frames for use in turbine towers, along with the ability to manufacture and supply pre-terminated leads offer considerable cost saving compared to traditional cable installation […]

Cable Protection For Hazardous Areas Using Flexible Conduit

Flexible conduit systems can provide a proven safe and cost effective protection solution for cabling installed in explosive atmospheres. Better safe than sorry is a sensible approach, but make sure that you are not fooled into unnecessarily expensive options warns Tim Creedon, Sales and Marketing Director for Flexicon. Explosive areas exist where a flammable mixture […]

Cable Theft Prevention

At its peak, cable theft was estimated to cost the UK economy £770 million per year. Even though a £5 million funded crackdown from British Transport Police (BTP) has helped dramatically reduce the level of cable theft, in the first half of this financial year, (up to 14th September 2013) there has been 95 incidents […]

ETS Have Received The FORS Bronze Award

ETS Cable Components have received the Fleet Operator Recognition Scheme (FORS) bronze award. The FORS accreditation scheme aims to improve fleet activity in London and throughout the UK and beyond. After carrying out an on-site audit we have now been officially recognised for the safety, greenness and efficiency of our delivery fleet. This latest accreditation […]

Blog

Blog