Cable Cleats & Cable Ties

Cable accessories such as Cable fixing cleats have been an integral product in our product range since ETS was formed in 1988 and whilst we show over 50 cable cleat products on our website, that does not cover the whole range. Over the years we have been called on to design and supply bespoke cable cleat products for certain project requirements where a standard product would not be suitable.

-

Raychem-RPG Banding Installation Tools

View products -

Raychem-RPG Coated Jaw-Type Buckles

View products -

Raychem-RPG Coated Steel Banding

View products -

Raychem-RPG Coated Wing-Type Buckles

View products -

Raychem-RPG Jaw-Type Buckles

View products -

Raychem-RPG Wing-Type Buckles

View products -

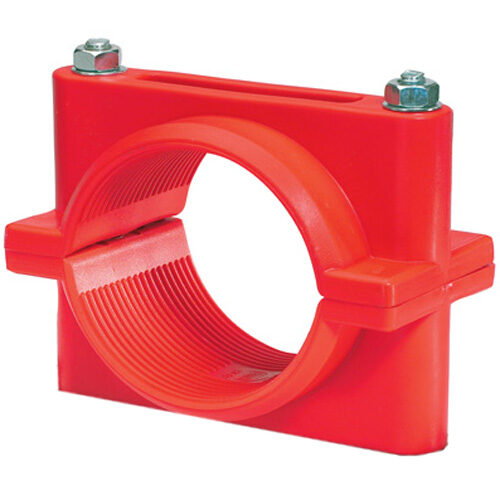

Red HV Cable Cleats

View products -

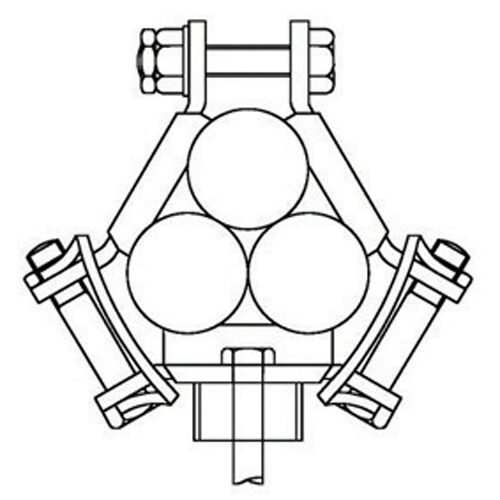

Single Bolt Atlas Trefoil Cable Cleats

View products -

Single Bolt Cable Cleat Fixing Kits

View products -

Stainless Steel RollerBall Cable Ties

View products -

Threaded Cleat Studs

View products -

Trefoil Cleat Fixing Kits

View products -

Two Bolt Cable Cleat Fixing Kits

View products -

Uncoated Stainless Steel Ladder Cable Ties

View products -

Vari-Cleat Multiple Cable Cleats

View products -

Vulcan+ Stainless Steel Cable Cleats

View products -

Zero Halogen Nylon Cable Ties – Black

View products

This has included designing a Kevlar coated trefoil cleat to protect against brake dust generated by fast trains, to providing Super Duplex stainless steel products which had to last for 40 years in a tunnel with the most aggressive of environmental conditions.

Some of these bespoke design cable cleats have gone on to become standard products in our range, such as the Phoenix stainless steel cleat which was designed in the 2000’s to help restrain fire performance cables which used to ensure vital circuits to continue operation in the event of a fire outbreak. More recently, we were asked by Network Rail to find a cleat solution to alleviate a critical health and safety issue and the result of this was the launch of the ‘No Bolts’ cleat.

With so many cable cleats and cable types now available, it can probably seem like a difficult choice to know which product you need. We can help to select the correct cable cleat for your installation and if none of the typical products in our range seem to be suitable, we will help design a solution.

Typical considerations when selecting a cleat type are conductor size, overall diameter, cable type / make-up, environmental factors and short circuit withstand requirement. The last point is very important as knowing this requirement will often help with determine cable cleat type and the required fixing spacings to keep a cable in situ in the event of a short circuit.